The Unknown Sense

The process of pottery which looks so tangible and has a direct connect of clay with the hand touch of the maker, apparently has an equal intangible force too.

Even though all the senses are involved in the process of pottery, there is an “unknown sense” which determines the final outcome. The craft of shaping clay requires a lot of patience, focus and hopefulness throughout the process where a potter needs to take a certain amount of risk. The risk has to be deliberate and welcoming, which is only possible if one has that keen “unknown sense”. This unknown sense is an intangible outcome of years of acquaintance and a unique art of interaction with the material. Pottery seems very easy when viewed from a distance but that is far from the reality.

This “unknown sense” follows the potter through each stage of making, since from identifying the ideal local clay to its firing.

While identifying the ‘ideal’ clay, the Kumbhar has his own set of rules to jugde its genuineness. The clay has to pass through his test of examination which starts with his rubbing with the nail, which should leave the clay shiny. For checking the impurities he would wet the dry clay in water and then approve it for firing. A sample test decides on the temperature (high or low) and further the potter chooses on the kind of products to be made with that particular clay.

There is a variety of clay available in the terrain of Kutch, which is both dry and marshy in some parts. The traditional potters have evolved their own methods of selection and procurement depending on the region and quality of the clay available to them.

Next is the process of Throwing, which looks like a mechanical production of identical objects. The potters never use any kind of measuring tools or rulers while production. They throw a pile of clay on wheel and keep making uniform masses in one go. The “unknown sense” brings the preciseness and uniformity while making.

Tapping or Ghadai is the most important skill in the potters of Kachchh. There were distinct shapes and forms achieved in this stage of tapping, which evolved uniquely in context of its usage by various communities. . Products were designed and engineered keeping their specific functions in mind.

The tools called kunera, a stone that is kept inside from mouth of the pot to support the wall while tapping with tipla, the wooden bat, from outside, are the heroes in the process and hence are very important to the Kumbhars.

“The pot while tapped in your lap behaves and reacts in a certain way as if it tells you where to start and stop. The right shape is attained while I constantly interact with my pot while making”, says Ramzubhai Kumbhar from Bhuj.

“tapping and shaping a pot is like growing your own child and giving the right amount of values for him to be an ideal human being. In the process, you sometimes have to be strict and even beat for him to realize the odds. Similarly, we beat the pots in order to attain its best ideal shape.”, says an elder potter from Bhuj.

The women potters in Kachchh are great painters and have their own sense of quirky finish with strokes, motifs and designs that naturally comes to them. Since from making of clay to beautifully painting the pots, women are an inevitable part in the process.

The painting styles also vary from women to women and region to region. They learn the process from their sisters or mothers and inherently grasp the details. Each motif has something to say and did evolve in the traditional times of making. Natural white clay, geru (red) and the black stone is used as the primary shades in Kutch pottery. Each pot is a unique piece painted with a bamboo brush called tiri.

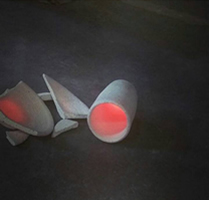

The ultimate test comes with the last stage of firing, where the potter discovers the initial faults if there is breakage or disuniformity in the color of pots. Since from loading, firing and again unloading the pots, the potter and his family keep their fingers crossed and are ready to face any sort of results.

Potters in Kutch mostly pit fire or use traditional updraft kilns.